Photoinitiator EMK Application scenarios

1. Revêtements durcissables aux UV

Wood coatings, plastic coatings, metal coatings; colored and black UV coatings

Absorbs long-wave UV light with strong penetration, suitable for curing deep layers and colored systems.

2. Encres à séchage UV

Offset printing inks, letterpress inks, flexographic inks; compatible with yellow-phase inks and varnishes

Provides fast, effective long-wave UV curing for various printing processes.

3. Electronic Chemicals

Serves as a sensitizer in liquid photoresists (key material for printed circuit board manufacturing)

Enhances imaging quality by boosting sensitivity within composite photoinitiator systems.

4. Autres applications

Adhesives, dye intermediates, photosensitizers, etc.

Versatile functionality allows use as intermediates or auxiliary agents.

💡 Technical Characteristics & Selection Recommendations

Curing Light Source Compatibility:

Compatible with both traditional mercury lamp sources and UV-LED sources, aligning with current eco-friendly and energy-efficient trends.

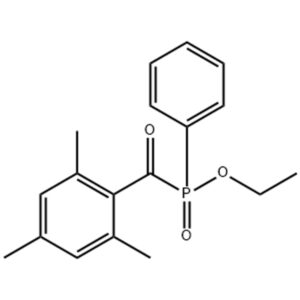

Mécanisme d'action :

As a Type II photoinitiator, it requires synergistic interaction with co-initiators (e.g., amine compounds). Some commercial EMK products incorporate amine functionality and may be used alone.

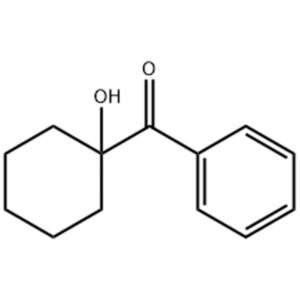

Propriétés physiques :

Typically appears as a pale yellow to off-white powder with a melting point around 93-95°C.

Commentaires

Il n'y a pas encore de commentaires.