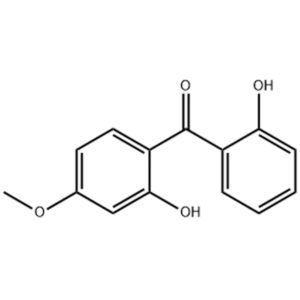

UV-1 Application scenarios

1. Polyurethane (PU) Products:

Used in PU foam materials (sponges), shoe materials, leather, sheets, and coatings, improving UV aging resistance and anti-yellowing performance, suitable for high-temperature PU processing applications.

2. Epoxy Resin Systems:

Suitable for LED encapsulation adhesives, chip potting compounds, transparent epoxy adhesives, and crystal clear resins, inhibiting yellowing during high-temperature curing and outdoor use, maintaining high light transmittance.

3. High-End Coatings and Adhesives:

Applied to automotive clear coats, industrial floor coatings, and epoxy adhesives, reducing color difference changes during outdoor use and extending the service life of components.

4. Rubber Products:

Used in various rubber products to delay aging, cracking, and fading caused by ultraviolet radiation, maintaining physical properties such as tensile strength and elasticity.

5. Synthetic Fibers and Outdoor Textiles:

Added to synthetic fibers such as polyester and nylon, as well as sunshades, tents, and outdoor clothing, to improve light stability and maintain appearance and performance.

6. Electronics and Specialty Materials:

Used in polymer encapsulation materials for electronic components and special transparent materials that require UV and thermal stability, ensuring long-term reliability.