IPAMA Monomer Application scenarios

1. Semiconductor Manufacturing

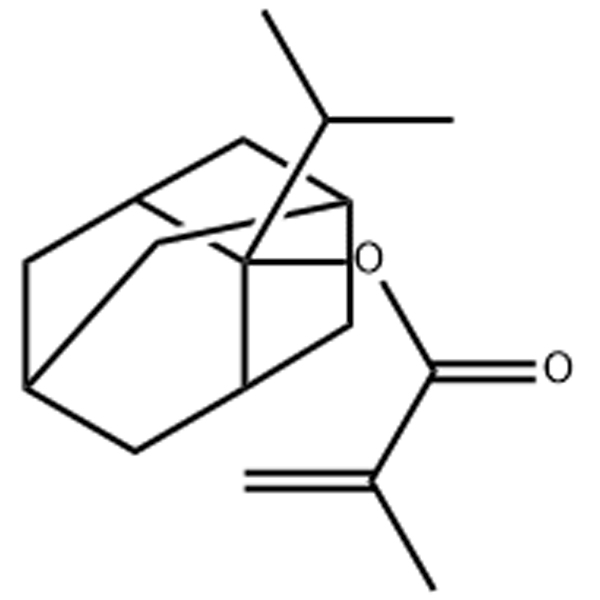

KrF/ArF Photoresist Monomers

Deliver alkaline dissolution contrast, high thermal stability, and excellent etch resistance for chip circuit patterning.

2. Advanced Material Synthesis

Structural units for sequence-controlled polymers

Leverages steric hindrance from bulky side chains to enable precise monomer addition, constructing functionally defined polymers with specified sequences.

3. Biomedical Research

Drug delivery systems, medical materials (under development)

Polymers exhibit excellent biocompatibility and stability, suitable for controlled drug release or as implant materials.

🏭 Primary Industrial Application: Semiconductor Photoresist

This represents IPAMA’s most mature and core industrial application. It primarily serves as a monomer for chemically amplified resist (CAR) in extreme ultraviolet (EUV) lithography processes such as KrF (248nm) and ArF (193nm).

Mechanism of Action:

During photolithography, the polymer formed by IPAMA polymerization undergoes acid-catalyzed decomposition of its ester groups on the side chains after exposure. This creates a significant difference in solubility between exposed and unexposed areas in alkaline developer solution, enabling precise transfer of circuit patterns onto silicon wafers.

Structural Advantages:

The adamantyl group in the IPAMA molecule exhibits exceptional chemical and thermal stability while providing excellent dry etch resistance. The introduction of the isopropyl group further modulates the monomer’s polarity and solubility, facilitating the achievement of high-resolution, high-contrast photolithographic patterns.

🧪 Cutting-Edge Research Applications: Sequence-Controlled Polymer Synthesis

IPAMA demonstrates unique value in academic research, particularly in sequence-controlled polymer synthesis requiring precise molecular structure control, owing to its bulky tertiary alkyl side chain.

Core Characteristics:

Its bulky “adamantyl-isopropyl” side chain induces significant steric hindrance during polymerization. This effect can be strategically leveraged to achieve “single-unit monomer addition” under metal-catalyzed radical polymerization (e.g., ATRP) conditions, where only one monomer molecule is precisely incorporated per reaction step.

Application Method:

Researchers can employ an “iterative synthesis” strategy: first add an IPAMA unit, then convert its bulky side chain into a standard carboxyl group via acid cleavage or similar methods, followed by functionalization. This initiates the next round of monomer addition. This process can be cycled repeatedly, precisely constructing polymers with pre-designed unit sequences and functions, much like building blocks.

Derrick Back -

Schnelle Lieferung, ausgezeichnete Qualität. Sehr zu empfehlen