Beschreibung

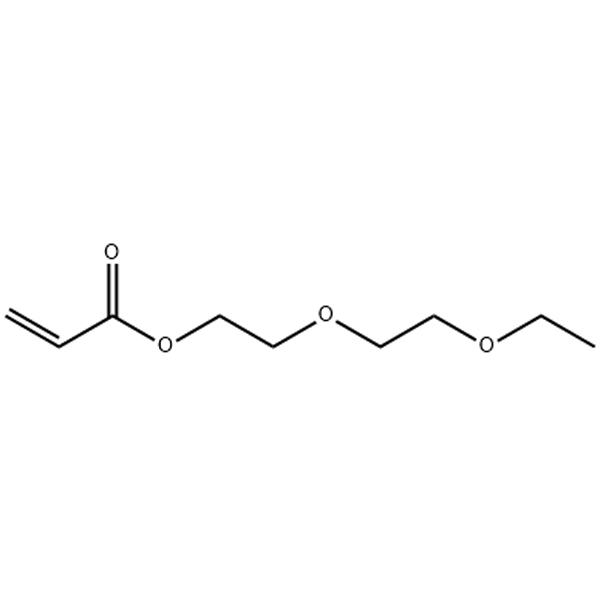

EOEOEA Monomer / 2-(2-Ethoxyethoxy)ethylacrylat CAS 7328-17-8

| Erscheinungsbild | Transparente Flüssigkeit |

| Polymerisationsinhibitor, ppm | ≤200 MEHQ |

| Feuchtigkeit, wt.% | 0.2 |

| Säurewert, mgKOH/g- | 0.5 |

| Farbe, APHA | ≤100 |

| Dichte , 25℃ | 1.08~1.11 |

| Viskosität , CPS.25℃ | 3~8 |

| Brechungsindex | 1.436 |

| Oberflächenspannung, dyn/cm | 29.7 |

| EOEOEA Tg,℃ | -56 |

Im weiten Feld der lichthärtenden Materialien sticht EOEOEA als Acrylatmonomer hervor, das eine wichtige Rolle bei der UV-Polymerisation verschiedener ungesättigter Systeme, wie UV-Lacke, UV-Farben und UV-Klebstoffe, spielt.

Bei eingehender Analyse ist seine hohe Flexibilität bemerkenswert. Im Gegensatz zu vielen herkömmlichen Monomeren ist EOEOEA eine weiche "Elfe", die den Materialien einzigartige flexible Eigenschaften verleiht. Bei der Verkapselungsbeschichtung einiger flexibler elektronischer Produkte beispielsweise verhindert diese hohe Flexibilität Risse im Material aufgrund von Biegung und gewährleistet so die Stabilität und Lebensdauer der elektronischen Komponenten.

Darüber hinaus sollte die Verdünnungsfähigkeit von EOEOEA nicht unterschätzt werden. Wenn und TPGDA, DPGDA, TMPTA und andere traditionelle Monomere im gleichen System, ist es wie ein leistungsfähiges "Verdünnungsmittel Schlüssel", kann effizienter die Viskosität des Systems anzupassen. Für eine High-End-UV-Tintenformulierung Forschung und Entwicklung, zum Beispiel nach der Zugabe von EOEOEA, die Fließfähigkeit der Tinte wurde erheblich verbessert, so dass der Druckprozess glatter, die Einheitlichkeit und Sättigung der Farbe wurde ebenfalls verbessert.

Darüber hinaus ist auch die gute Haftung ein wichtiger Aspekt, insbesondere bei Kunststoffen ist EOEOEA wie ein treuer "Haftungswächter". In der Vergangenheit, in der frühen Entwicklung der Oberflächenbeschichtungstechnologie für Kunststoffe, war die Adhäsion immer ein Problem, und viele Monomere sind schwierig, den gewünschten Effekt zu erzielen. Das Aufkommen von EOEOEA hat eine neue Ära für die Oberflächenbehandlung von Kunststoffen eingeleitet. In der modernen dekorativen und schützenden Beschichtungsprozess von Kunststoff-Produkten, kann es eng an die Kunststoff-Oberfläche, ob in der täglichen Verschleiß oder in der Erosion von komplexen Umgebungen, kann sicherstellen, dass die Integrität und Haltbarkeit der Beschichtung, stark erweitert die ästhetische und praktische Zyklus von Kunststoff-Produkten geklebt werden.

Angenommen, dass es im Bereich der Forschung und Entwicklung neuer Materialien in der Zukunft mit dem kontinuierlichen Fortschritt von Wissenschaft und Technologie möglich sein wird, durch die Verbindung von EOEOEA mit einigen aufkommenden Nanomaterialien eine Art von Supermaterialien mit Superhaftung, hoher Flexibilität und besonderen Funktionen (wie Selbstreparatur, Anti-Bakterien usw.) zu schaffen. Dies ist zweifellos eine neue Richtung, die es wert ist, eingehend untersucht und erforscht zu werden, und die, wenn sie erfolgreich ist, zu einem neuen Wandel in der Anwendung von Materialien in vielen Bereichen wie Luft- und Raumfahrt, Biomedizin und High-End-Fertigung führen wird.

EOEOEA-Anwendungen

Holzbeschichtungen, PVC-Beschichtungen, Kunststoffbeschichtungen, Metallbeschichtungen, Offsetdruckfarben, Flexodruck, Siebdruck, Lacke und Klebstoffe.

EOEOEA Verpackung und Versand

Verpackung: 25 kg/Fass oder 200 kg/Fass

Lieferung: innerhalb von 5-7 Arbeitstagen.

EOEOEA Speicherung

Sie werden in einem trockenen, sauberen Lager mit guter Belüftung aufbewahrt.

Vermeiden Sie Licht- und Hitzeeinwirkung.

Schutz des Produkts vor Auslaufen, Regen und Sonneneinstrahlung während des Transports.

Kontaktieren Sie uns jetzt!

Wenn Sie eine Preis- und Musterprüfung benötigen, tragen Sie bitte Ihre Kontaktdaten in das unten stehende Formular ein. Wir werden uns in der Regel innerhalb von 24 Stunden mit Ihnen in Verbindung setzen. Sie können mir auch eine E-Mail schicken info@longchangchemical.com während der Geschäftszeiten ( 8:30 bis 18:00 Uhr UTC+8 Mo.~Sa. ) oder nutzen Sie den Live-Chat auf der Website, um eine schnelle Antwort zu erhalten.

| Polythiol/Polymercaptan | ||

| CHLUMICRYL®DMES Monomer | Bis(2-mercaptoethyl)sulfid | 3570-55-6 |

| CHLUMICRYL® DMPT Monomer | THIOCURE DMPT | 131538-00-6 |

| CHLUMICRYL® PETMP Monomer | 7575-23-7 | |

| CHLUMICRYL® PM839 Monomer | Polyoxy(methyl-1,2-ethandiyl) | 72244-98-5 |

| Monofunktionelles Monomer | ||

| CHLUMICRYL® HEMA Monomer | 2-Hydroxyethylmethacrylat | 868-77-9 |

| CHLUMICRYL® HPMA-Monomer | 2-Hydroxypropylmethacrylat | 27813-02-1 |

| CHLUMICRYL® THFA Monomer | Tetrahydrofurfurylacrylat | 2399-48-6 |

| CHLUMICRYL® HDCPA Monomer | Hydriertes Dicyclopentenylacrylat | 79637-74-4 |

| CHLUMICRYL® DCPMA-Monomer | Dihydrodicyclopentadienylmethacrylat | 30798-39-1 |

| CHLUMICRYL® DCPA Monomer | Dihydrodicyclopentadienyl-Acrylat | 12542-30-2 |

| CHLUMICRYL® DCPEMA Monomer | Dicyclopentenyloxyethylmethacrylat | 68586-19-6 |

| CHLUMICRYL® DCPEOA Monomer | Dicyclopentenyloxyethylacrylat | 65983-31-5 |

| CHLUMICRYL® NP-4EA Monomer | (4) ethoxyliertes Nonylphenol | 50974-47-5 |

| LA Monomer | Laurylacrylat / Dodecylacrylat | 2156-97-0 |

| CHLUMICRYL® THFMA Monomer | Tetrahydrofurfurylmethacrylat | 2455-24-5 |

| CHLUMICRYL® PHEA Monomer | 2-PHENOXYETHYLACRYLAT | 48145-04-6 |

| CHLUMICRYL® LMA Monomer | Laurylmethacrylat | 142-90-5 |

| CHLUMICRYL® IDA Monomer | Isodecylacrylat | 1330-61-6 |

| CHLUMICRYL® IBOMA Monomer | Isobornylmethacrylat | 7534-94-3 |

| CHLUMICRYL® IBOA Monomer | Isobornylacrylat | 5888-33-5 |

| CHLUMICRYL® EOEOEA Monomer | 2-(2-Ethoxyethoxy)ethylacrylat | 7328-17-8 |

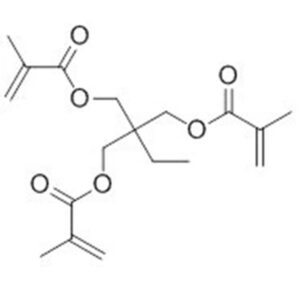

| Multifunktionelles Monomer | ||

| CHLUMICRYL® DPHA Monomer | 29570-58-9 | |

| CHLUMICRYL® DI-TMPTA Monomer | DI(TRIMETHYLOLPROPAN)TETRAACRYLAT | 94108-97-1 |

| Acrylamid-Monomer | ||

| CHLUMICRYL® ACMO Monomer | 4-Acryloylmorpholin | 5117-12-4 |

| Difunktionelles Monomer | ||

| CHLUMICRYL® PEGDMA Monomer | Poly(ethylenglykol)dimethacrylat | 25852-47-5 |

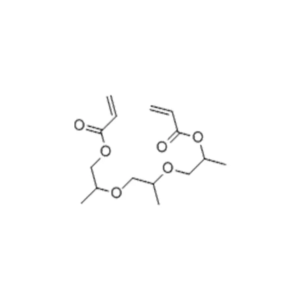

| CHLUMICRYL® TPGDA Monomer | Tripropylenglykol-Diacrylat | 42978-66-5 |

| CHLUMICRYL® TEGDMA Monomer | Triethylenglykol-Dimethacrylat | 109-16-0 |

| CHLUMICRYL® PO2-NPGDA Monomer | Propoxylat-Neopentylenglykol-Diacrylat | 84170-74-1 |

| CHLUMICRYL® PEGDA Monomer | Polyethylenglykol-Diacrylat | 26570-48-9 |

| CHLUMICRYL® PDDA Monomer | Phthalat Diethylenglykol-Diacrylat | |

| CHLUMICRYL® NPGDA Monomer | Neopentylglykol-Diacrylat | 2223-82-7 |

| CHLUMICRYL® HDDA Monomer | Hexamethylen-Diacrylat | 13048-33-4 |

| CHLUMICRYL® EO4-BPADA Monomer | ETHOXYLIERTES (4) BISPHENOL-A-DIACRYLAT | 64401-02-1 |

| CHLUMICRYL® EO10-BPADA Monomer | ETHOXYLIERTES (10) BISPHENOL-A-DIACRYLAT | 64401-02-1 |

| CHLUMICRYL® EGDMA Monomer | Ethylenglykol-Dimethacrylat | 97-90-5 |

| CHLUMICRYL® DPGDA Monomer | Dipropylenglykol-Dienoat | 57472-68-1 |

| CHLUMICRYL® Bis-GMA Monomer | Bisphenol A Glycidylmethacrylat | 1565-94-2 |

| Trifunktionelles Monomer | ||

| CHLUMICRYL® TMPTMA Monomer | Trimethylolpropantrimethacrylat | 3290-92-4 |

| CHLUMICRYL® TMPTA Monomer | Trimethylolpropantriacrylat | 15625-89-5 |

| CHLUMICRYL® PETA Monomer | 3524-68-3 | |

| CHLUMICRYL® GPTA ( G3POTA ) Monomer | GLYCERIN-PROPOXYTRIACRYLAT | 52408-84-1 |

| CHLUMICRYL® EO3-TMPTA Monomer | Ethoxyliertes Trimethylolpropantriacrylat | 28961-43-5 |

| Photoresist Monomer | ||

| CHLUMICRYL® IPAMA Monomer | 2-Isopropyl-2-adamantylmethacrylat | 297156-50-4 |

| CHLUMICRYL® ECPMA Monomer | 1-Ethylcyclopentylmethacrylat | 266308-58-1 |

| CHLUMICRYL® ADAMA Monomer | 1-Adamantylmethacrylat | 16887-36-8 |

| Methacrylat-Monomer | ||

| CHLUMICRYL® TBAEMA Monomer | 2-(Tert-Butylamino)ethylmethacrylat | 3775-90-4 |

| CHLUMICRYL® NBMA Monomer | n-Butylmethacrylat | 97-88-1 |

| CHLUMICRYL® MEMA Monomer | 2-Methoxyethylmethacrylat | 6976-93-8 |

| CHLUMICRYL® i-BMA Monomer | Isobutylmethacrylat | 97-86-9 |

| CHLUMICRYL® EHMA Monomer | 2-Ethylhexylmethacrylat | 688-84-6 |

| CHLUMICRYL® EGDMP Monomer | Ethylenglykol-Bis(3-mercaptopropionat) | 22504-50-3 |

| CHLUMICRYL® EEMA Monomer | 2-Ethoxyethyl-2-methylprop-2-enoat | 2370-63-0 |

| CHLUMICRYL® DMAEMA Monomer | N,M-Dimethylaminoethylmethacrylat | 2867-47-2 |

| CHLUMICRYL® DEAM Monomer | Diethylaminoethylmethacrylat | 105-16-8 |

| CHLUMICRYL® CHMA Monomer | Cyclohexylmethacrylat | 101-43-9 |

| CHLUMICRYL® BZMA Monomer | Benzylmethacrylat | 2495-37-6 |

| CHLUMICRYL® BDDMP Monomer | 1,4-Butandiol Di(3-mercaptopropionat) | 92140-97-1 |

| CHLUMICRYL® BDDMA Monomer | 1,4-Butandioldimethacrylat | 2082-81-7 |

| CHLUMICRYL® AMA Monomer | Allylmethacrylat | 96-05-9 |

| CHLUMICRYL® AAEM Monomer | Acetylacetoxyethylmethacrylat | 21282-97-3 |

| Acrylate Monomer | ||

| CHLUMICRYL® IBA Monomer | Isobutyl-Acrylat | 106-63-8 |

| CHLUMICRYL® EMA Monomer | Ethylmethacrylat | 97-63-2 |

| CHLUMICRYL® DMAEA Monomer | Dimethylaminoethylacrylat | 2439-35-2 |

| CHLUMICRYL® DEAEA Monomer | 2-(Diethylamino)ethylprop-2-enoat | 2426-54-2 |

| CHLUMICRYL® CHA Monomer | Cyclohexylprop-2-enoat | 3066-71-5 |

| CHLUMICRYL® BZA Monomer | Benzylprop-2-enoat | 2495-35-4 |

| Sonstiges Monomer | ||

| CHLUMICRYL® MCPMA Monomer | 1-Methylcyclopentylmethacrylat | 178889-45-7 |

| CHLUMICRYL® TMPMP Monomer | Trimethylolpropan Tris(3-mercaptopropionat) | 33007-83-9 |

| CHLUMICRYL® CTFA Monomer | Zyklisches Trimethylopropanformalacrylat | 66492-51-1 |

| CHLUMICRYL® HPHPDA Monomer | 30145-51-8 | |

| CHLUMICRYL® MPEG Monomer | 26915-72-0 | |

Bewertungen

Es sind noch keine Bewertungen vorhanden.